Mr Yan

Leave a messageProduct Description

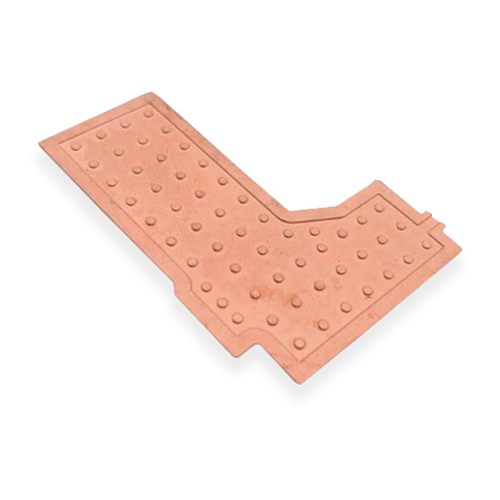

Vacuum Cavity Heat Plate technology is similar in principle to a heat pipe, but differs in the way it conducts heat. Heat pipe is a one-dimensional linear heat conduction, while the heat in the vacuum cavity heat plate is conducted on a two-dimensional surface, so the efficiency is higher.

Product parameters

Size: Maximum size: 400MMX 400MM

Thickness: 1.0mm (MM) or more

Substance: Refrigerant

Microstructure: Multi-layer fibre capillary structure, regionalisation of hole size design

Cavity material: Oxygen-free copper (C1100/C1020)

External structure: Oxygen-free copper (C1100/C1020)

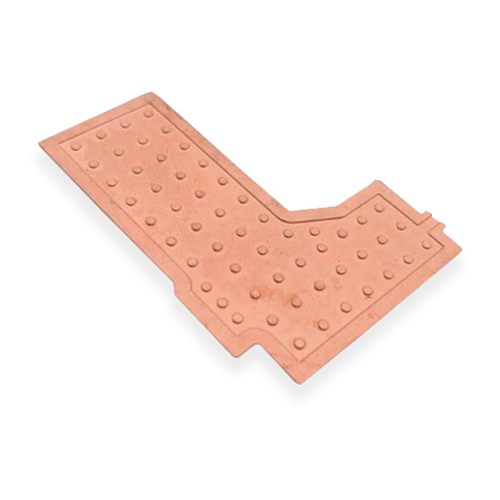

Product Name: Uniform Temperature Module Plate

Category: Thermal Management / Heat dissipation module

Application: Electronics, power modules, battery packs, optical modules, and high-precision instruments.

The Uniform Temperature Module Plate is a high-efficiency thermal solution designed to maintain an even temperature distribution across electronic components. This module integrates advanced heat conduction technology, such as vapor chambers or heat pipes, ensuring uniform heat spreading and rapid dissipation.

It is especially suited for scenarios where thermal hotspots must be avoided and where stable operating temperatures are crucial to device reliability. The modular structure allows for flexible integration into different systems, from servers and communication devices to EV battery packs and industrial control equipment.

Key Features:

Rapid thermal equalization with minimal temperature difference

Lightweight and compact structure

Compatible with various heat sources (CPU, GPU, power modules, etc.)

Customizable size and shape

Long service life and high reliability

Characteristics

Low start-up temperature; fast heat transfer; good temperature uniformity: high output power: low manufacturing cost; long service life, lighter weight.

Applications

is especially suitable for the heat dissipation needs in the narrow space environment where the height and space are strictly limited. Such as notebook computers, computer workstations and network servers. Very suitable for high junction temperatures, the need for rapid step-by-step cooling of the working environment. Such as high-power LED heat dissipation, semiconductor cooling wafer hot end heat dissipation and thermal power generation, the average temperature plate as a heat transfer element, can provide the electronics industry and a variety of other industries in the heat dissipation needs.

Structure

by the bottom plate and cover plate composed of a completely closed flat plate cavity, the cavity wall is equipped with liquid-absorbing capillary core structure, the capillary core structure can be wire mesh, micro-grooves, fibre filaments, but also metal powder sintered core and the composite combination of several structures. Cavity internal support structure is necessary to overcome the negative pressure due to vacuum caused by depression, heat rise, installation pressure deformation. When the heat conduction to the evaporation area, the work material in the cavity in the low vacuum environment, will begin to produce the phenomenon of liquid-phase vapourization, at this time the work material to absorb heat energy and the volume of the rapid expansion of the vapour-phase work material will soon fill the entire cavity, when the vapour-phase work material contact with a colder region will produce the phenomenon of condensation, through the phenomenon of condensation to release the heat accumulated in the evaporation, after the liquid-phase condensation of the liquid-phase work material by microstructure capillary phenomenon and then the liquid-phase work material to the evaporation. After condensation, the liquid-phase substance returns to the heat source of evaporation through the capillary phenomenon of microstructure, and this operation will be carried out again and again in the chamber, which is the operation mode of the equalisation plate. And because the microstructure can generate capillary force during the evaporation of the substance, the operation of the plate is not affected by gravity.

FAQ

Q1: What is the purpose of a Uniform Temperature Module Plate?

A1: Its main purpose is to evenly distribute heat across electronic components, preventing hotspots and improving the performance and stability of devices.

Q2: What technologies are used inside the plate?

A2: Most plates use vapor chamber or heat pipe technology for quick thermal equalization.

Q3: Can this module be customized for specific devices?

A3: Yes, we offer OEM/ODM customization including shape, size, material, and interface designs.

Q4: What industries commonly use this product?

A4: Widely used in servers, data centers, EV batteries, 5G communication equipment, industrial automation, and precision electronics.

Q5: How is this product different from a standard heat sink?

A5: Unlike conventional heat sinks that rely on passive surface area, this module spreads heat uniformly using internal conduction technology, leading to more stable and efficient cooling.

Product Description

Vacuum Cavity Heat Plate technology is similar in principle to a heat pipe, but differs in the way it conducts heat. Heat pipe is a one-dimensional linear heat conduction, while the heat in the vacuum cavity heat plate is conducted on a two-dimensional surface, so the efficiency is higher.

Product parameters

Size: Maximum size: 400MMX 400MM

Thickness: 1.0mm (MM) or more

Substance: Refrigerant

Microstructure: Multi-layer fibre capillary structure, regionalisation of hole size design

Cavity material: Oxygen-free copper (C1100/C1020)

External structure: Oxygen-free copper (C1100/C1020)

Product Name: Uniform Temperature Module Plate

Category: Thermal Management / Heat dissipation module

Application: Electronics, power modules, battery packs, optical modules, and high-precision instruments.

The Uniform Temperature Module Plate is a high-efficiency thermal solution designed to maintain an even temperature distribution across electronic components. This module integrates advanced heat conduction technology, such as vapor chambers or heat pipes, ensuring uniform heat spreading and rapid dissipation.

It is especially suited for scenarios where thermal hotspots must be avoided and where stable operating temperatures are crucial to device reliability. The modular structure allows for flexible integration into different systems, from servers and communication devices to EV battery packs and industrial control equipment.

Key Features:

Rapid thermal equalization with minimal temperature difference

Lightweight and compact structure

Compatible with various heat sources (CPU, GPU, power modules, etc.)

Customizable size and shape

Long service life and high reliability

Characteristics

Low start-up temperature; fast heat transfer; good temperature uniformity: high output power: low manufacturing cost; long service life, lighter weight.

Applications

is especially suitable for the heat dissipation needs in the narrow space environment where the height and space are strictly limited. Such as notebook computers, computer workstations and network servers. Very suitable for high junction temperatures, the need for rapid step-by-step cooling of the working environment. Such as high-power LED heat dissipation, semiconductor cooling wafer hot end heat dissipation and thermal power generation, the average temperature plate as a heat transfer element, can provide the electronics industry and a variety of other industries in the heat dissipation needs.

Structure

by the bottom plate and cover plate composed of a completely closed flat plate cavity, the cavity wall is equipped with liquid-absorbing capillary core structure, the capillary core structure can be wire mesh, micro-grooves, fibre filaments, but also metal powder sintered core and the composite combination of several structures. Cavity internal support structure is necessary to overcome the negative pressure due to vacuum caused by depression, heat rise, installation pressure deformation. When the heat conduction to the evaporation area, the work material in the cavity in the low vacuum environment, will begin to produce the phenomenon of liquid-phase vapourization, at this time the work material to absorb heat energy and the volume of the rapid expansion of the vapour-phase work material will soon fill the entire cavity, when the vapour-phase work material contact with a colder region will produce the phenomenon of condensation, through the phenomenon of condensation to release the heat accumulated in the evaporation, after the liquid-phase condensation of the liquid-phase work material by microstructure capillary phenomenon and then the liquid-phase work material to the evaporation. After condensation, the liquid-phase substance returns to the heat source of evaporation through the capillary phenomenon of microstructure, and this operation will be carried out again and again in the chamber, which is the operation mode of the equalisation plate. And because the microstructure can generate capillary force during the evaporation of the substance, the operation of the plate is not affected by gravity.

FAQ

Q1: What is the purpose of a Uniform Temperature Module Plate?

A1: Its main purpose is to evenly distribute heat across electronic components, preventing hotspots and improving the performance and stability of devices.

Q2: What technologies are used inside the plate?

A2: Most plates use vapor chamber or heat pipe technology for quick thermal equalization.

Q3: Can this module be customized for specific devices?

A3: Yes, we offer OEM/ODM customization including shape, size, material, and interface designs.

Q4: What industries commonly use this product?

A4: Widely used in servers, data centers, EV batteries, 5G communication equipment, industrial automation, and precision electronics.

Q5: How is this product different from a standard heat sink?

A5: Unlike conventional heat sinks that rely on passive surface area, this module spreads heat uniformly using internal conduction technology, leading to more stable and efficient cooling.